INDUSTRY

Powder Metallurgy (P/M) parts are produced by mixing carefully selected

metal powders, compacting them at room temperature in precision

die, then heating (sintering) the resulting shapes to complete the

metallurgical

bond between the powder particles. After sintering, parts usually

have the required tolerances, mechanical properties and surface finish

specified

in the drawing of the parts. Thus raw materials utilization is

nearly 100% and manufacturing steps and costs are kept to a minimum.

If necessary,

the parts may be machined, heat-treated, forged or otherwise

processed further for even greater precision or strength.

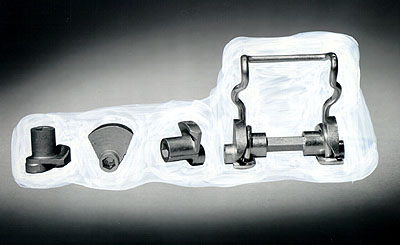

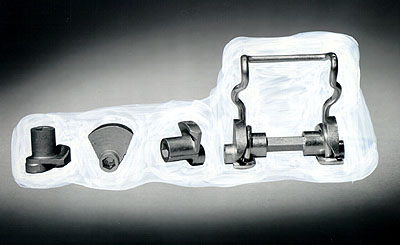

First parts produced by National Sintered Alloys

Design engineers in many industries depend on P/M for cost effective

production of products that have repeatable tolerance, high mechanical

properties and long life. Products are used in automotive engines,

transmissions, and chassis, computers, aircraft, agriculture, off-road

machinery, business machines, hardware, instruments and hydraulics

industries.

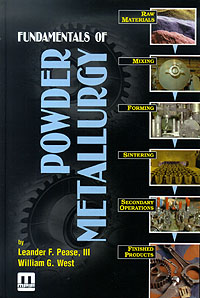

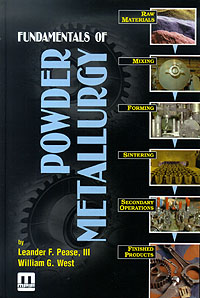

Fundamentals of Powder Metallurgy

By William G. West and Leander F. Pease, III

To order this book log onto: www.mpif.org

|